Maextro

Improving Princes’ Production Accuracy in Food Manufacturing through BOM and Routing Optimisation

For Princes, one of the UK’s leading food and beverage manufacturers, reliable data is more than just a back-office requirement; it’s the foundation of safe, efficient, and scalable production. With operations spanning multiple plants across the UK and Europe, Princes manages a diverse product portfolio that feeds into supermarkets, foodservice operators, and wholesale suppliers.

Yet the systems underpinning its manufacturing data told a different story. Bills of Materials (BOMs) and Routings (the lifeblood of production accuracy) were being managed through a patchwork of semi-automated processes, Excel spreadsheets, and manual approvals. The result was a lack of visibility, inconsistent information, and vulnerabilities that posed real risk to product integrity and time to market.

To overcome this, Princes partnered with Bluestonex to implement Maextro, a Master Data Management solution, to mov from fragmented, error-prone processes to a centralised, rule-based system that safeguards data quality and accelerates operations.

About the Client

Client: Princes Foods

Industry: Food & Beverage Manufacturing

Headquarters: United Kingdom

Employees: 1,000+

Markets: Retail, foodservice, wholesale, manufacturing supply chains

Princes is a major international group supplying both branded and private-label food and drink products across the UK and Europe. Operating in more than 20 categories, the company combines large-scale manufacturing with an extensive distribution network, ensuring consistent supply to retailers, wholesalers, and foodservice operators. With this complexity comes a critical need: reliable, standardised data to support production accuracy, compliance, and growth.

Business Challenges

Before Maextro, Princes faced the all-too-common pitfalls of legacy processes in SAP:

-

Inconsistent and incomplete data from manual entry

-

Human error undermining BOM and Routing accuracy

-

Operational inefficiencies driven by rework and delays

-

Lack of traceability in change processes

For a food and beverage manufacturer, the stakes were high. Poor master data didn’t just slow operations—it risked compliance, product quality, and customer trust. Princes needed a robust governance model to ensure data integrity, streamline workflows, and prepare for future scalability.

Engagement and Solution Journey

When Princes set out to address its master data challenges, the objective was clear: eliminate fragmented spreadsheets, embed governance directly into SAP, and create a sustainable model for accurate and efficient manufacturing data management.

Bluestonex utilised a design thinking approach, engaging closely with both technical and manufacturing teams. Rather than a one-size-fits-all rollout, the project was delivered in agile iterations—allowing users to see changes early, provide feedback, and build confidence in the new system.

At the heart of the transformation was Maextro, an SAP-native Master Data Management solution. By replacing offline tools with structured, rule-based workflows, Maextro embedded governance into the everyday processes that mattered most: Bills of Materials and Routings.

Key elements of the solution included:

-

Digital Specification Forms – Legacy Excel templates were replaced with structured, dynamic Maextro forms enriched with configurable rules and validations.

-

Workflow Automation – BOM and Routing changes flowed through governed, auditable approval processes, reducing reliance on manual checks.

-

Seamless Notifications – Users received real-time SAP and Office365 email alerts, ensuring responsibilities were clear and actioned quickly.

-

Role-based Controls – Layered security and configurable rules enforced authorisations beyond SAP’s standard capabilities.

-

Ease of Maintenance – All rules and workflows were managed through IMG configuration, eliminating the need for external development.

The result was a system that not only standardised data but also embedded compliance and efficiency directly into the fabric of Princes’ SAP environment. What once required multiple spreadsheets, offline sign-offs, and back-and-forth email chains was now a streamlined, governed workflow with complete visibility and accountability.

A New Way of Working

The workflow was an important aspect of Maextro’s delivery and lives natively without the need for a business rule framework consultant or complex HCM Organisational Structure. A refined process with distributed responsibilities was created to capture and approve data, which was adopted by the manufacturing departments.

Both SAP notifications and office365 email notifications were adopted by users as Maextro has the ability to provide external email or SAP internal notification as well as Fiori app notifications.

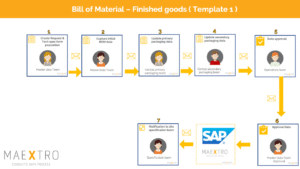

Below is the process adopted by our client for SAP BoM (Finished Goods) processing

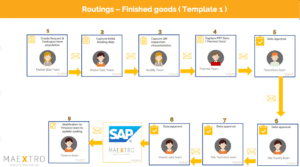

Below is the process adopted by our client for SAP Routing processing.

Results & Impact

The introduction of Maextro marked a step change in how Princes managed its manufacturing master data. What had once been a fragmented, manual, and error-prone process was replaced with a governed, digital framework that provided both efficiency and confidence in the accuracy of production-critical information.

The impact was felt across multiple areas of the business:

-

Data consolidation – All legacy Excel templates and offline processes were retired, with data now created and maintained directly through Maextro’s dynamic forms.

-

Improved accuracy and compliance – Configurable field-level validations reduced the risk of human error and enforced consistent, production-ready data.

-

Governed approvals – A structured workflow ensured that BOM and Routing changes were reviewed, authorised, and tracked, improving traceability.

-

Efficiency gains – Automation replaced manual steps, significantly reducing delays caused by rework and data issues.

-

Scalability and agility – New objects and processes can now be rolled out quickly without dependency on external development resources.

Perhaps most importantly, Princes gained a foundation for long-term reliability and scalability. By embedding governance directly into its SAP environment, the business is better positioned to ensure product integrity, accelerate time-to-market, and prepare for its future transition to S/4HANA.

Looking Ahead

With successful deployments for BOM and Routing processes, Princes is now poised to extend Maextro across additional master data domains, including Material Master for Traded Goods and Engineering Stores. This expansion will further consolidate governance, reduce reliance on manual processes, and embed automation throughout the manufacturing lifecycle.

The platform’s in-built configurability ensures that future rollouts can be delivered quickly, without dependency on external consultants or custom development. By maintaining control within SAP and leveraging Maextro’s agile framework, Princes can continue to innovate, improve operational efficiency, and ensure high-quality, consistent data across all production processes.

Looking forward, this foundation not only strengthens day-to-day operations but also positions Princes for a smooth transition to S/4HANA, unlocking further digital potential and enabling the business to respond rapidly to market demands and growth opportunities.

Ready to explore how Maextro could support your transformation? Check out more success stories or learn more on the Maextro product page.